Home » Case studies » UKCA marking confectionery machinery

UKCA marking confectionery machinery

Working with one of our close allies in controls and panel manufacture, Cenheard UKCA marked a series of upgraded machines for a leading confectionery client…

To ensure full compliance with The supply of Machinery (Safety) Regulation 2008, our close ally contacted Cenheard to conduct the full UKCA marking of 9 upgraded confectionary flow wrapping machines.

Following our six steps to UKCA marking, Cenheard where able to provide our client with simple guidance for compliance and a full technical file for each machine.

Get in touch

Get the help you need on your upcoming project and feel confident that you have the right expertise on hand to guide you through the complex world of regulations and national standards. Click the button below to contact us direct…

Guidance areas

Cenheard are experts in machinery safety and provided the client with support in the following areas:

- The supply of Machinery (Safety) Regulations 2008

- Electrical Equipment (Safety) Regulations 2016

- Electromagnetic Compatibility Regulations 2016

- BS EN ISO 13849 compliant safety circuit verification via SISTEMA

- Safety function and validation tests in line with BS EN ISO 13849 (SFT’s)

- Essential Health and Safety Requirements (EHSR’s)

- Complete technical file

Realised benefits

By employing Cenheard for their UKCA marking needs, our ally could relax and concentrate on the machine upgrade without the worry of creating a full UKCA mark compliant technical file. Cenheard started by determining which regulations the machinery would be required to comply with. The supply of Machinery (Safety) Regulation 2008, Electrical Equipment (Safety) Regulations 2016 and Electromagnetic Compatibility Regulations 2016.

Using this information we determined an Annex VIII (Internal checks) conformity assessment would be sufficient in line with The supply of Machinery (Safety) Regulation 2008.

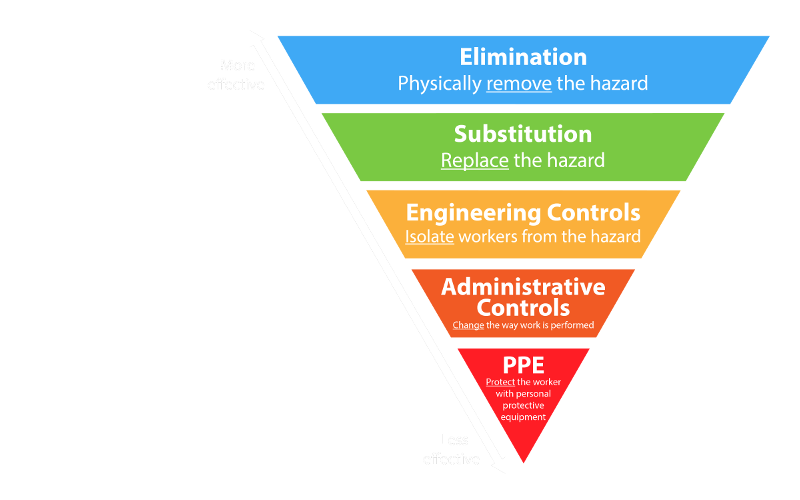

To kick things off Cenheard conducted a design risk assessment in line with BS EN ISO 12100 RA. Ensuring all relevant EHSR’s where covered through the hierarchy of controls. Identifying all the relevant British standards the equipment needed to comply with.

The client was then able to implement all the required changes and begin upgrading the machinery. Cenheard are vital in machinery design to ensure all relevant standards are met and simplified for the client.

Conducting a PLr study from the 12100 RA to allow the client to design the SRP/CS, a guard survey so the client could ensure compliance with BS EN ISO 14120 / 13857 and a SISTEMA report to test compliance with BS EN ISO 13849.

From this Cenheard could start compiling the technical file ensuring full compliance with The supply of Machinery (Safety) Regulation 2008. Issuing the client with the full technical file required by regulation and a soft copy for the end user.

Discover more case studies

Interested to learn more about our work? Discover more our proudest moments and highest achievements through our online library of case studies…

A quote for exactly what you need

Click the button below to get a quote bespoke to your needs. We work closely with you to understand your exact needs. We aim to be competitive while delivering on your expectations and what you need to make your workplace as safe as possible…