The purpose of this introduction to manual handling is ensure that you understand the requirements and objectives of current manual handling legislation.

In this introduction you will gain an understanding of the manual handling process and the techniques used. Along with the correct approach to reduce the risk of injury.

Introduction

Why is correct manual handling important?

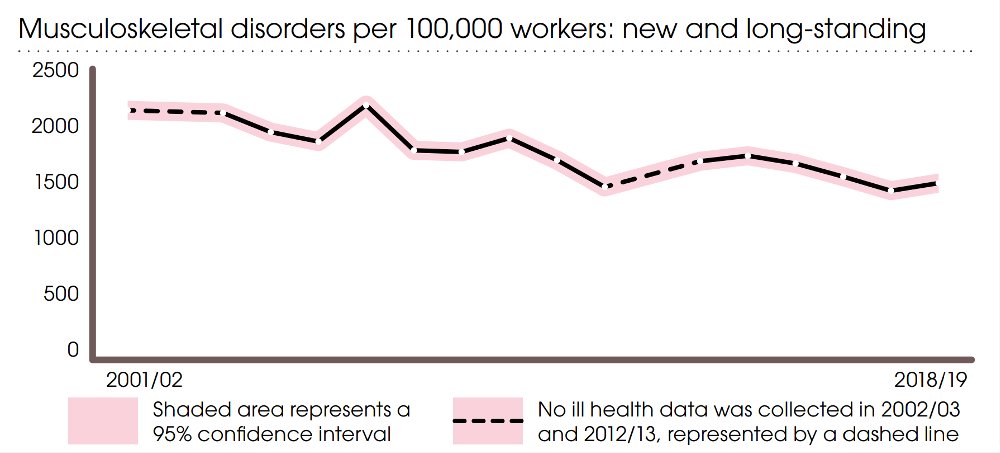

From the HSE statistical graph, the general trend for musculoskeletal disorders is downwards. This could be attributed to a continual improvement in manual handling training across all sectors. Training is essential as it improves awareness…

- Awareness reduces risk

- Shared awareness reduces accidents

Impact on people and business

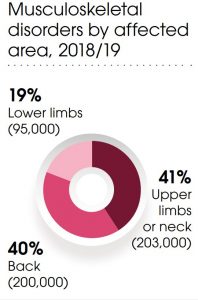

The main cause for working days lost in 2018 was musculoskeletal conditions (such as back and neck pain), leading to 6.9 million days lost.

498,000 workers are currently suffering from work-related Musculoskeletal Disorders.

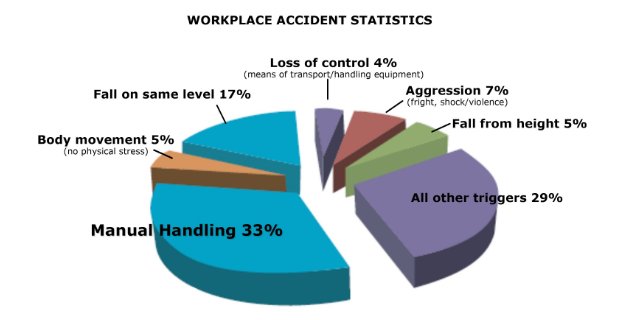

A third of all workplace accidents are down to poor manual handling.

Definition of manual handling

Any transporting or supporting of a load by hand or bodily force. This includes the lifting, putting down, pushing, pulling, carrying or moving of any load.

Examples of manual handling

Manual handling legislation

- Great Britain

- Manual Handling Operations

- Northern Ireland

- Manual Handling Operations Regulations (Northern Ireland)

- Republic of Ireland

- Safety, Health and Welfare at Work (General Application) Regulations

Health and safety legislation

The health and safety acts define specific duties…

Duties

Manual handling regulations

Where applicable, these regulations place the following duties on the employer and employees:

Employers are required to...

So far as is reasonably practicable, the health, safety and welfare of employees.

Employees are required to...

General duties

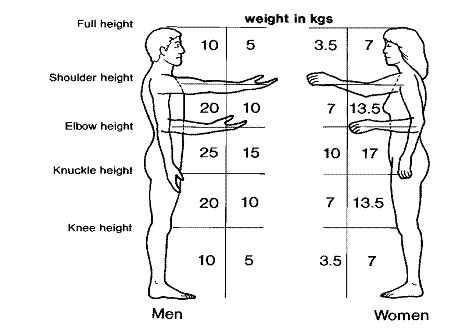

How much weight can a person lift?

Any person should lift only what they feel comfortable and able to lift.

Plan and prepare - risk assessment

A suitable and sufficient risk assessment is required to suitably plan and prepare for manual handling activities.

T.I.L.E. analysis

One useful method to plan, prepare and assess a manual handling tasks is T.I.L.E.

Task, Individual, Load and Environment are the four areas to review and establish how best to perform the manual handling operation.

Task in TILE

Step 1 - Why move the load?

Step 2 - Consider how best to carry out the task

Step 3 - Who needs to be involved?

Step 4 - Are any manual handling aids needed for the task?

Step 5 - Where is the load going?

Step 6 - How quickly does the task need to be carried out?

Step 7 - How often does the task occur?

Individual in TILE

Points to consider about the individual performing the manual handling operation.

Aggravating back pain

- Carrying objects awkwardly

- Sudden movements of loads

- Pulling or dragging excessive loads

- Stooping, bending over or poor posture

- Lifting objects which are too heavy or bulky

- Working beyond normal abilities and limits, and when physically overtired

Best practices

Load in TILE

- How heavy are the loads?

- How much do they weigh?

- Are the loads being moved frequently?

- Are the loads bulky or unwieldy?

- Are the loads difficult to grasp?

- Are the loads unstable or unpredictable?

- Are the loads intrinsically harmful? (e.g. sharp / hot)

Environment in TILE

- Are there any constraints on posture?

- Are the floor surfaces in an suitable condition?

- Are the variations in floor levels?

- Is the environment hot, cold or humid?

- What is the condition of the lighting and light levels??

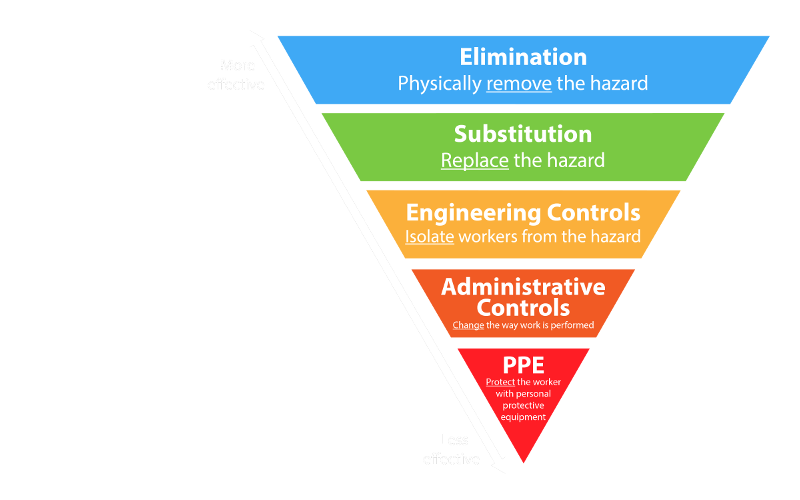

The hierarchy of control

As with all Health & Safety risk assessments, the hierarchy of control is a very useful tool.

#1 - Elimination

Does the manual handling operation have to be performed at all?

Can the same outcome be achieved without the need for a manual handling operation?

By asking ourselves such questions before starting a manual handling task, we may be able to eliminate the hazard and risk of injury altogether.

#2 - Substitution

Can the same outcome be achieved without have to manually handle the load?

Are there lifting tools and/or equipment that could be used to perform this task?

Could an automated transport system be used instead of people?

Analysing substitutes is a great way of finding safer ways to achieve the same task.

#3 - Engineering controls

For manual handling engineering controls usually focus on ergonomics and the processes that are implemented during the transportation of a load.

For example, using ergonomic benches and table tops the optimised in height to limit bending and stretching.

Engineering controls may also include non slip floors, walkways, trolleys and lifting jacks.

#4 - Administration

Administrative control measures incorporate training to improve awareness.

As discussed a previous lesson, awareness reduces risks, shared awareness in a workplace reduces accidents. This is why training is so important and should always be a defined administrative control in any manual handling operation.

Other administrative controls include detailed analysis of RSIs (Repetitive Strain Injuries) in line with ART (Assessment of Repetitive Tasks). This usually incorporate the revision of break times to minimise risks associated with repetitive tasks.

#5 - PPE, the last resort

As with any strategy to control hazards within the workplace, PPE is the last resort.

Types of PPE that have become common in the workplace and aid manual handling could include:

- Steel toe cap boots

- Protective gloves

- Protective sleeves

- Hard hats

- High visibility jackets

Adding PPE can provide a false sense of security, which can undermine your efforts. Also, the improper use of PPE can increase risks those who are trying to avoid them.

Our advice is be cautious when opting for PPE as a control measure. Always ask yourself this…

“Can I further use the hierarchy of control to mitigate the risks and reduce the requirement for PPE”

Understanding injuries

Many injuries associated with manual handling include…

- Lower back pain

- Upper limb disorders (ULDs)

ULDs are problems with the shoulders and arms, including the forearm, elbow, wrist, hand and fingers.

Musculoskeletal Disorders are short or long term manual handling injuries.

Short term / superficial injuries

- Cuts

- Bruises

- Sprains

- Tears

- Small fractures

- Muscle strain

Long term injuries

Long term injuries mainly involve damage to the musculoskeletal system of the body, including…

- Muscles

- Tendons

- Bones

- Joints

- Ligaments

- Nerves

- Blood Vessels

These injuries are usually caused by long-term, gradual wear-and-tear as a result of repetitive strenuous activities or incorrect handling techniques.

Overexertion

‘To overexert’ is defined as to strain, or put too much pressure. The injuries caused by overexertion are serious and account for over 6.9 million working days lost each year. Pushing your body past its limits can lead to physical exhaustion, fatigue, and hypoglycemia, among other serious injuries.

Overexertion is a common cause of accidents resulting in injury. Injuries resulting from overexertion can be easily avoided with simple preventions.

Physical overexertion

Physical overexertion is a common cause of injury. These injuries are typically caused by repetitive motion, for example, lifting heavy items or working in an awkward position. These injuries often cause acute pain, and without proper treatment, this acute pain can lead to chronic pain and lifelong problems, such as carpal tunnel syndrome and osteoarthritis.

Fatigue

Pushing your body or mind too hard for too long can leave you feeling fatigued and exhausted; a lack of quality sleep is another common cause of fatigue-related injuries. Sleep is essential to your health; it allows your body and mind to recharge, heal, and develop properly. Inadequate sleep can have severe impact on the body including increased risk of mistakes and accidents, increased blood pressure, and decreased cognitive functions.

Hypoglycemia

Forgetting to eat, or not eating proper meals, can contribute to overexertion and can cause hypoglycemia (also known as low blood sugar). The symptoms differ from one person to another and can range from mild to severe, but can include headaches, confusion, tiredness, and more.

More serious issues, including coma and death, can arise if you have an underlying condition, such as diabetes.

Prevention of overexertion injuries

The good news is that most injuries related to overexertion are preventable. Approximately 20% of injuries are associated with pushing and pulling work demands.

Research has shown that most of these overexertion “accidents” are caused by the “unsafe acts of persons”. This is as opposed to “unsafe mechanical or physical conditions.” Human failure such as poor body mechanics is the main cause of accidents.

Prevention of physical overexertion

- Lift lighter loads

- Take frequent breaks

- Stretch regularly

Prevention of fatigue

- Get 7-8 hours of sleep

- Reduce caffeine

- Reduce alcohol

Prevention of Hypoglycemia

- Eat regularly

- Carry a healthy snack

- Manage diabetes

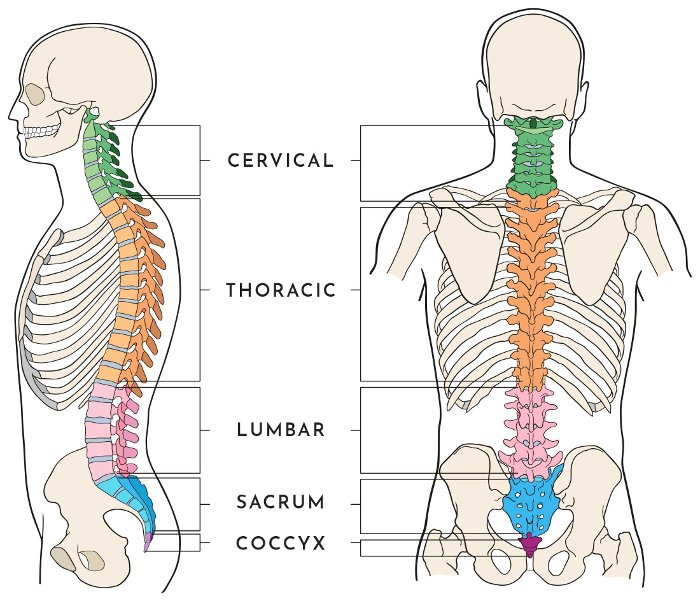

Spinal injuries

- To protect the spinal cord

- To allow movement

- To support the upper body

Anatomy of the spine

In human anatomy, the vertebral column (backbone or spine) is a column usually consisting of 33 vertebrae.

Each vertebrae is separated by intervertebral discs.

The spine houses and protects the spinal cord in its spinal canal.

YOU ONLY GET ONE BACK!

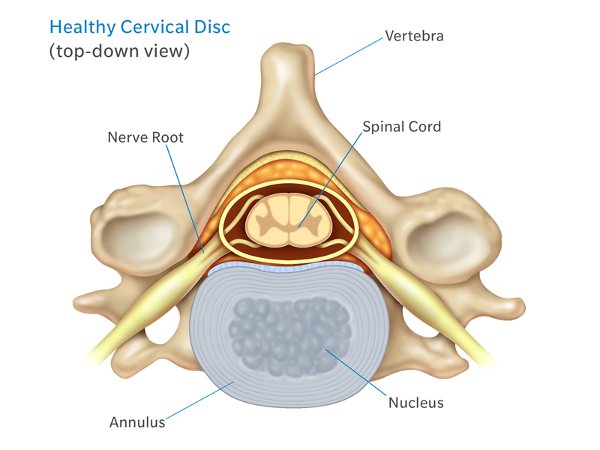

The spinal nerve

Your spinal nerve is a mixed nerve, which carries motor, sensory and autonomic signal between the spinal cord and the body.

In the human body there are 31 pairs of spinal nerves, one on each side of the vertebral column.

Spinal disc

- To allow slight movement of the vertebrae

- To act as a ligament to hold the vertebrae together.

- To function as a shock absorber for the spine.

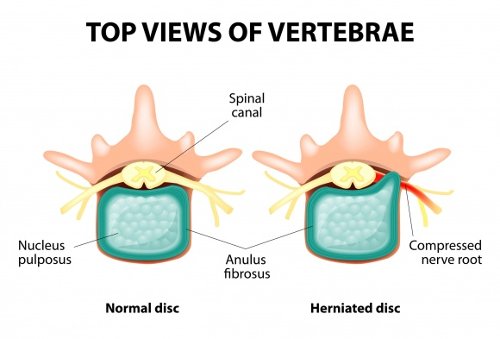

Slipped disc

The most common injury caused by incorrect manual handling techniques is a herniated/prolapsed/slipped disc.

This occurs when the disc cracks open allowing the nucleus to seep out, in close proximity to the spinal nerve.

This puts pressure onto the nerves resulting in severe pain.

This is often the result of poor handling techniques over a long period rather than a single event.

Correct lifting techniques

Step 1 - Stop and Think

Plan work that involves manual handling…

- How heavy is the load?

- Where is it going to be placed?

- Use appropriate handling aids where possible.

- Will assistance be required?

- Remove obstructions, such as discarded wrapping materials.

For long lifts, such as from floor to shoulder height, consider resting the load mid-way on a table or bench to change grip.