Introduction

This is a introductory guide to working at height, it will outline some of the important safety perimeters you will require to safely complete your task.

What is working at height?

- work above ground/floor level

- could fall from an edge, through an opening or fragile surface or

- could fall from ground level into an opening in a floor or a hole in the ground

Work platforms

- Roof

- Floor

- Platform on a scaffold

- The treads of a stepladder

- Mobile elevating work platforms (MEWPs)

Fragile surfaces

The regulations define fragile surfaces as “a surface which would be liable to fail if any reasonably foreseeable loading were to be applied to it”.

Fragile surfaces can be horizontal or near vertical structures or panels — e.g. roof panels, skylights, covers, etc. — which could collapse or break if walked on or loaded with tools or materials.

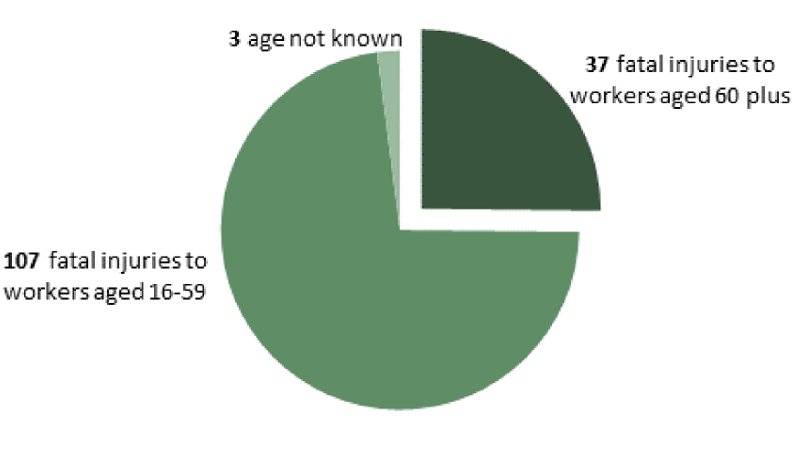

2018-2019 HSE statistics show...

- 147 Work related Deaths 2018/2019

- Victims 95% Male

- Over 60’s 25% of fatality’s

- 40 Deaths from falls from height

- Falls from Height 27% of Deaths

- Estimated 336,000 days lost due to Non-fatal Falls from height

Legislation

England, Scotland and Wales

- Work at Height Regulations 2005

Northern Ireland

- Work at Height Regulations (NI) 2005

Republic of Ireland

- Safety, Health and Welfare at Work (General Application) Regulations 2007 – Part 4 Work at Height

Employees duties

Employees have general legal duties to take reasonable care of themselves and others who may be affected by their actions, and to co-operate with their employer to enable their health and safety duties and requirements to be complied with.

Employers duties

Employers and those in control of any work at height activity must make sure work is properly planned, supervised and carried out by competent people. This includes using the right type of equipment for working at height. Low-risk, relatively straightforward tasks will require less effort when it comes to planning. Employers and those in control must first assess the risks.

Planning

Planning is the first step to wards reducing the risks associated with working at height.

Safety requirements

Hierarchy of control measures

For every task that needs to be done at height you need to assess the risk and put appropriate control measures in place. There is a hierarchy of control measures that you need to follow. You only move up the hierarchy when you decide that the control is not practicable.

#1 Avoid

Avoid the need to work at height where ever possible. This can often be achieved by using equipment that extends from the ground.

#2 Prevent

Prevent falls using appropriate access equipment, such as work platforms.

#3 Reduce

Reduce the distance and consequences of a fall should one occur.

Considering control measures

You should choose collective measures to prevent falls (such as mobile elevating work platforms – MEWPs) before other measures that may only mitigate the distance and consequences of a fall (such as fall protection systems) or which may only provide personal protection from a fall.

Think – Do I have the correct training? Is my training up to date? Have I read and understood control measures?

Remember – Do not use equipment your not trained on. Do not use faulty or outdated safety equipment. Ask any questions or concerns before staring your task.

Competence

Competence can be described as the combination of training, skills, experience and knowledge that a person has and their ability to apply them to perform a task safely. Other factors, such as attitude and physical ability, can also affect someone’s competence.

If you still believe the potential for risk is still too high refuse to do the task, safety is always the number one priority. You can always re-plan, but you can never go back.

Equipment

There is lots of equipment available that can help reduce the risks of working at height.

Scaffolding

There are many different types of scaffolding such as suspended, stationary, temporary or countervailed. All of which will include rails and boards for your safety.

Mobile Elevated Work Platforms (MEWP's)

Relevant and up to date training is required for the safe use all types of MEWP’s.

- aerial platform

- vertical lift

- powered access

- spider lift

- cherry picker

- scissor lift

- aerial work platform

- boom lift

- access platform

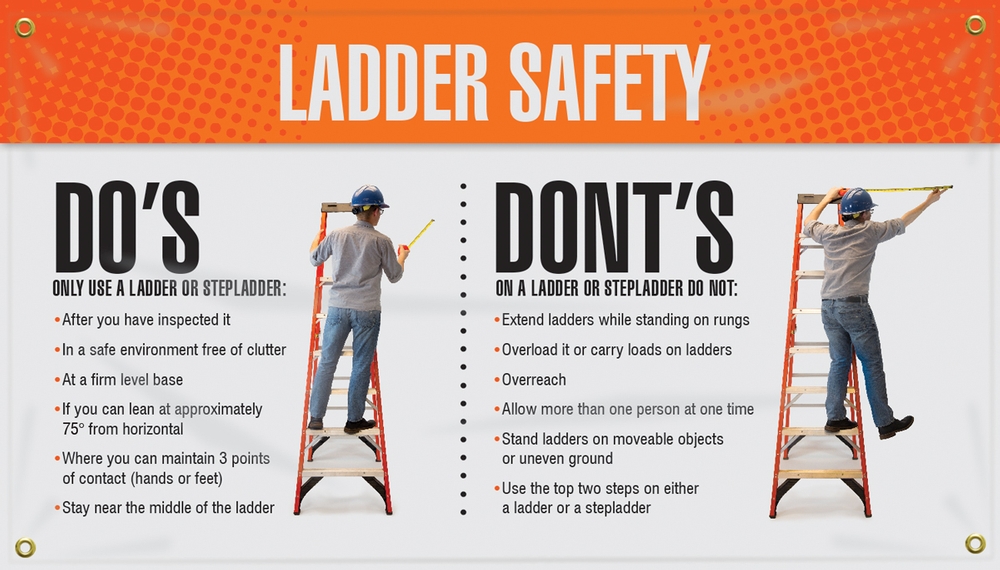

Ladders

A ladder is a vertical or inclined set of rungs or steps. They come in different sizes and materials. Always use the most appropriate type and size of ladder for the task.

Fall protection equipment

Collective safety measures are always preferable such as hand rails installed to prevent falls, grated covers over sky lights and restrictive access to high risk areas.

Fall restraint

Fall Restraint systems prevent you from falling.

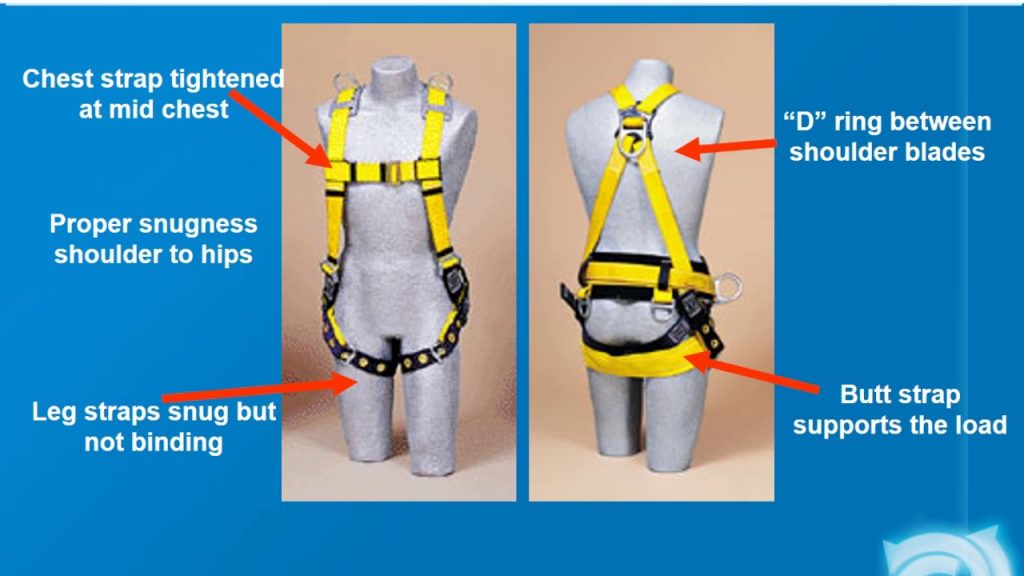

They use a body holding device (Harness) connected to a reliable anchor, preventing you from reaching areas where the potential of fall exists.

In the hierarchy of controls , restraint is preferred to fall arrest equipment. Compared to a fall arrest system, fall restraint systems does not require a rescue plan.

Sometimes, due to restricted free fall distances (e.g. low building height, vehicles, racking or machinery in or around the building reducing available height to have the fall arrested safely), a restraint system would be the only choice.

Fall arrest

Fall arrest systems protect you after you fall; they stop the fall before you hit the surface.

These systems use a body holding device (harness) connected to a reliable anchor; they arrest and restrict a fall preventing you from colliding with the ground or structures, whilst limiting the forces on the body.

When you are working near a fragile surface, narrow ledge or unusual building or roof shape and are using lanyards or a rope, there is a good chance you might fall off or into the building. This is when you need a fall arrest system, together with personal protective equipment (PPE). You also need additional training and, by law, you are required to have a rescue plan in place. This means that you can be retrieved as soon as possible should you fall.

Safety harness

Always use a harness as per manufactures instruction.

The label on a safety harness must be in place, intact and legible while the safety harness is in use.

The label will display the serial number which can be traced back to the certificate issued by the manufacturer.

If the label is damaged or missing the harness must not be used.