Introduction

The aim of this toolbox talk is to increase staff awareness of fire safety within the workplace. More specifically, how to deal with hot works.

The use of regular toolbox talks, if done effectively, will significantly improve the safety culture within your organisation. This will increase the safety awareness of the workers, and as a result reduce the likelihood of accidents and unsafe occurrences.

Legislation references

- Health & Safety at Work Act 1974

- Fire Safety Regulations 2022

Hot work awareness

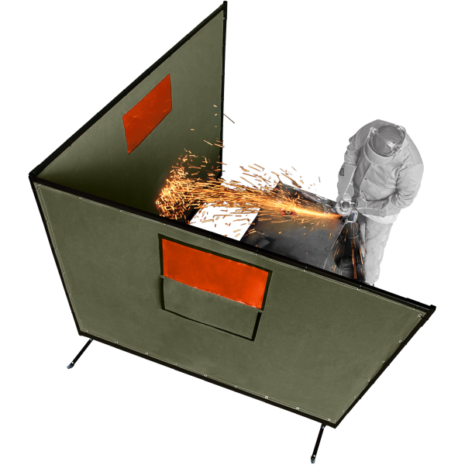

Remember, fire kills! Hot work is any activity that generates flames, sparks or heat, including:

- Arc welding

- Brazing

- Cutting

- Grinding

Pre hot work checks

- Ensure the area is clear of combustible materials

- Consider the passage of sparks that may occur

- Consider splatter or other hot emissions

- Consider hot gases or radiation that may be emitted

- Make sure a suitable fire extinguisher is available and ready for use

- Check the risk assessment and method statement

- Obtain a ‘Permit to Work’ document

Hot work in progress

- Ensure all Permit to Work conditions are being achieved

- Make sure that your escape route remains available

- Mark the area and keep unauthorised persons away

- Use safety signs as appropriate

- Ensure all hot processes are monitored

- Do not leave the area unattended

On completion of hot work

- Ensure all equipment is removed or isolated

- Ensure all smouldering materials are extinguished

- Check adjacent areas for signs of fire

- Stop hot work 1-hour before leaving site

- Complete a 1-hour post-job check (30 minutes after stopping work) to ensure the area remains free from fire, smoke or fume

- Remove any exclusions or barriers

- Clear all tools and equipment

- Advise local managers that hot works have been completed and the area is safe

- Close permit to work