Introduction

The aim of this toolbox talk is to increase staff awareness of the importance of conducting thorough pre-start up checks at the start of their shift, prior to using industrial production machinery.

The use of regular toolbox talks, if done effectively, will significantly improve the safety culture within your organisation. This will increase the safety awareness of the workers, and as a result reduce the likelihood of accidents and unsafe occurrences.

Legislation references

- Health & Safety at Work Act 1974

- Management of Health and Safety at Work Regulations 1999

Pre-start up checks awareness

A general, pre-shift inspection is a very important part of a machine operator’s job. Never operate a machine without conducting a thorough pre-shift inspection. Skimming over the inspection checklist, could easily result in you overlooking a very important defect with the equipment, which could result in serious injury to you or your co-workers.

It may seem like you’re answering the same questions each day (and you are) and that you’re looking at the same parts everyday (and you are) but it is important. Components used in factory machinery get a lot of use during your shift, and faults do occur.

Industrial components not only have an expected operating life span, but they are also susceptible to stresses and strains. Items wear and become unserviceable. These may not show up at first but may become noticeable over time. You always want to be the one who finds a fault BEFORE it poses a risk to your safety, or the safety of others.

Safety devices

All safety devices are sold with a mean time to fail specification. This means that they are known to fail eventually. Machine designers use this information to ensure that the correct components are used, however this is an AVERAGE time to fail specification. You are the last safeguarding measure to ensure the machine is not only safe to use, but it will actually stop when you really need it to.

Emergency stops

Emergency stop pushbuttons are there to provide you with a means of stopping the machine should you or a co-worker find themselves in a dangerous or life-threatening scenario. Testing these devices at the start of your shift is the best action you can take to make sure that the inbuilt safety systems will protect your safety when you really need them to.

Guarding and guard switches

Guards are there to make sure you cannot access dangerous parts of machinery, even if you trip and fall over. They’re not in place tool look pretty, they’re there to protect you and your co-workers.

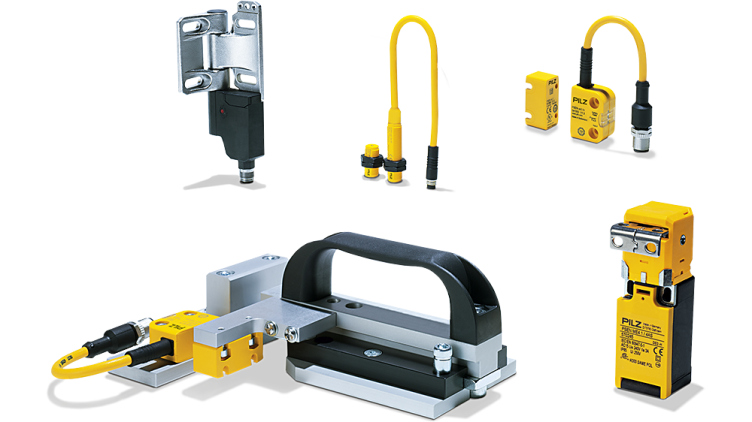

Guard switches and interlock devices are there to make sure the machine will not run when movable guards, such as doors and gates, are not in the correct position to protect you from danger. Like all safety devices these can fail. By checking their operation at the start of your shift, you’re protecting yourself and those around you.

Finding a defect

- Stop the machine

- Report the fault

- Wait for an engineer to carry out the repair and sign it off as safe to use

Never us a machine that cannot protect you from danger. Let’s all go home safe!