Introduction

Todays increasingly automated industrial environments, mean machinery safety is not just a compliance requirement. It is fundamental to those responsible for design and operation.

The critical component within this area is the Safety Related Parts of Control Systems (SRP/CS). These parts perform safety functions designed to protect personnel and equipment.

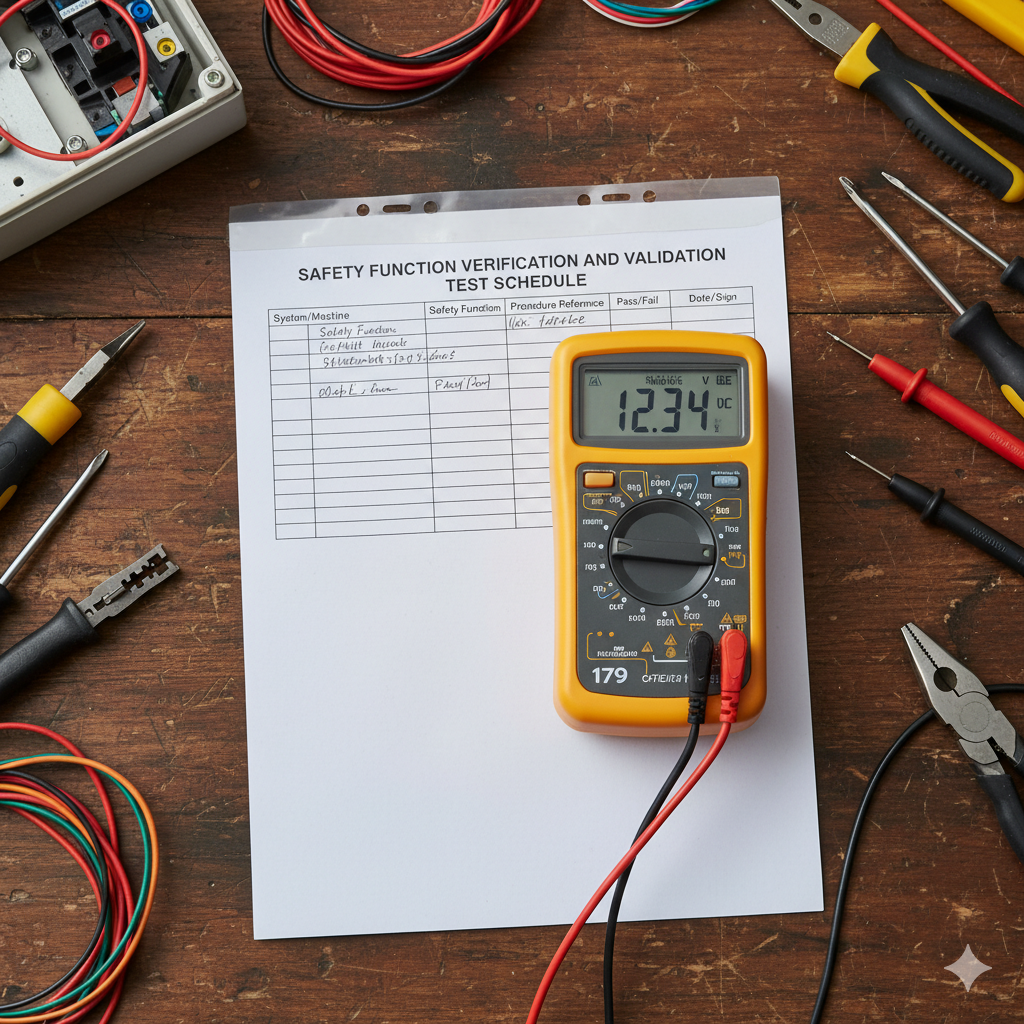

To ensure these systems perform as expected when needed, engineers must conduct a safety function and validation test. A structured process to verify that all parts of the safety circuit operate as intended.

What is a safety function and validation test?

There are multiple forms to a safety function and validation test (SFT), depending on who is conducting them. Today we are going to look at the end user.

Cenheard recommend end users conduct an SFT at least once per annum. This is alongside standard pre-use checks. Both must be done before equipment’s use. The end user SFT allows in-house engineers to assess the SRP/CS responds exactly as designed by the OEM.

The document outlines each input safety device and the expected reaction of each safety component within the SRP/CS upon activation. Providing a simple and quick test to ensure no modifications have been made to an equipment SRP/CS.

Why do safety function and validation tests matter?

Cenheard understands that as machines are installed / maintained certain measures are taken to allow full diagnostic coverage of the equipment. During which time SRP/CS can be bypassed / overridden by competent personnel in order to complete their checks of the equipment.

As with all human interaction, human error can take place. Cenheard have seen this first hand when an OEM forgot to remove a door link and handed over an unsafe machine to a client.

By conducting a SFT the end user will get validation that the equipment they own, and use is safe for their personnel. And any human error will be identified before it puts their personnel at risk.

Conclusion

Safety function tests play a pivotal role in ensuring equipment is maintained safely and does not put personnel at risk in line with regulation five of PUWER.

By implementing SFT’s into your planned maintenance activities you can ensure that your personnel are safe. This simple document adds the extra protection and validation you need to know your SRP/CS function as expected no matter the scenario in which they are used.